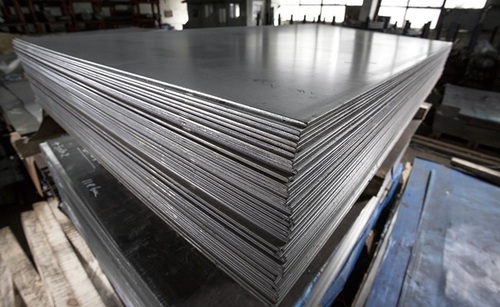

SS Fabrication Raw Material

Price 170 INR/ Kilograms

SS Fabrication Raw Material Specification

- Coating Type

- None / Self-Finished

- Heat Resistance

- Yes

- Tensile Strength

- 515 620 MPa (varies by grade)

- Recyclable

- Yes

- Product Form

- Raw Sheet, Plate, Bar, Pipe, Channel, Angle

- Size

- Customizable

- Corrosion Resistant

- Yes

- Hardness

- HRB 80 90 (varies by grade)

- Diameter

- Standard and Custom Sizes

- Material Composition %

- Varies: Cr 18-20%, Ni 8-10%, Fe Balance

- Product Name

- SS Fabrication Raw Material

- Steel Type

- Stainless Steel

- Steel Product Type

- Plate, Sheet, Rod, Pipe, Angle, Channel

- Grade

- 304, 316, 202, or as specified

- Thickness

- 0.5 mm to 50 mm

- Shape

- Rectangular, Square, Circular, Custom Shapes

- Steel Standard

- ASTM, JIS, DIN, EN, IS Standard

- Surface

- Polished, Matt, 2B, BA, No.1, No.4

- Composition

- Fe, Cr, Ni, Mn, Si, C (Varying as per Grade)

- Application

- Industrial Fabrication, Construction, Structural Support, Architecture, Manufacturing

- Dimension (L*W*H)

- Customized as Per Requirement

- Weight

- Depends on Size and Thickness

- Color

- Silver, Metallic Grey

- Material Grade

- SS 304/316/202

- Finish Type

- Polished / Mill Finish

- Usage

- Fabrication, Industrial Application, Structural Uses

- Machinability

- Good, varies by grade and surface finish

- Packaging Type

- Standard seaworthy or as requested

- Lead Time

- Depends on quantity and specifications

- Weldability

- Excellent, suitable for all standard processes

- Magnetic Properties

- Non-magnetic in annealed condition (304/316)

- Storage Condition

- Store in dry and covered area to prevent contaminants

- Elongation

- 40% (for SS304)

- Density

- 7.9 g/cm

About SS Fabrication Raw Material

Stainless steel fabricators are professionals who specialize in transforming stainless steel material into functional and aesthetically pleasing products. They use various tools and equipment to fabricate, shape, and weld stainless steel parts and components.Versatile Solutions for Industrial Fabrication

SS Fabrication Raw Material is engineered to cater to the dynamic needs of industries such as construction, architecture, structural support, and manufacturing. Whether you require plates, sheets, rods, or custom-shaped profiles, these stainless steel products are available in various grades and finishes, providing flexible solutions to match project specifications and performance expectations.

Unmatched Durability and Corrosion Resistance

With carefully balanced compositions including chromium and nickel, these stainless steel grades offer outstanding toughness, resistance to corrosion, and the ability to withstand high temperatures. The material is perfect for demanding environments and applications where long-term durability and low maintenance are crucial.

FAQs of SS Fabrication Raw Material:

Q: How should SS Fabrication Raw Material be stored to maintain its quality?

A: SS Fabrication Raw Material should be stored in a dry and covered area to prevent exposure to moisture and contaminants, ensuring the material retains its original properties and finish until use.Q: What are the main benefits of using SS Fabrication Raw Material for industrial fabrication?

A: The key benefits include excellent weldability, high corrosion and heat resistance, customization options, and good machinability. These properties make it ideal for long-lasting and reliable industrial and structural applications.Q: When is SS Fabrication Raw Material most commonly used?

A: It is widely utilized in construction, architectural structures, industrial fabrication, and manufacturing whenever durable, corrosion-resistant, and high-strength components are required.Q: Where can SS Fabrication Raw Material be supplied from?

A: This material can be sourced from dealers, distributors, exporters, fabricators, importers, manufacturers, retailers, service providers, suppliers, and wholesalers across India.Q: What is the process for selecting the right grade and finish for a project?

A: Selection depends on the applications requirements for corrosion resistance, mechanical strength, machinability, and aesthetics. Consultation with material specialists and referencing industry standards like ASTM, JIS, or DIN helps ensure the optimal grade and surface finish are chosen.Q: How is the lead time determined for orders of SS Fabrication Raw Material?

A: The lead time for delivery is based on the orders quantity, specific grade, dimensions, and finish. Larger or highly specialized orders may require additional processing time.Q: What is the typical usage of SS Fabrication Raw Material across industries?

A: Common uses include fabrication of structural supports, architectural elements, machinery parts, and components requiring precise dimensions and consistent performance, thanks to its strength and adaptability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Fabrication Category

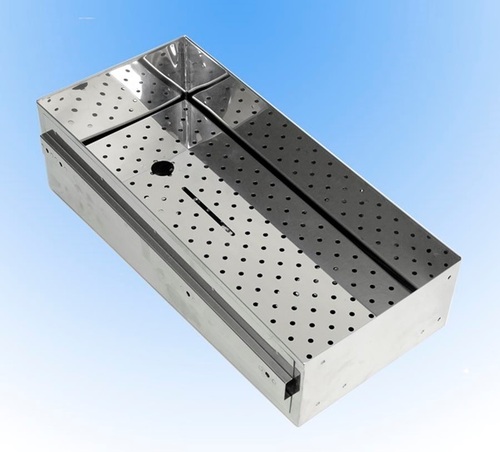

SS Fabrication

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Steel Product Type : Other, Fabricated Component

Application : Other, Structural, Industrial, Commercial, Architectural, Fabrication Works

Corrosion Resistant : Yes

Size : Custom sizes as per request

Stainless Steel Fabrication Raw Material

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Steel Product Type : Other, Sheet, Plate, Coil, Bar

Application : Other, Industrial Fabrication, Construction, Manufacturing, Automotive Parts

Corrosion Resistant : Yes

Size : Custom sizes available

Fabricated Steel Steel

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Steel Product Type : Other, Fabricated structural steel

Application : Other, Structural construction, industrial frameworks, building and infrastructure.

Corrosion Resistant : Optional with galvanized or painted coating

Size : Custom as per customer requirement

Stainless Steel Fabrication

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Steel Product Type : Other, Fabricated Product/Component

Application : Other, Industrial Components, Architectural Structures, Custom Equipment, Interior/Exterior Decor

Corrosion Resistant : Yes

Size : Custom sizes available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS