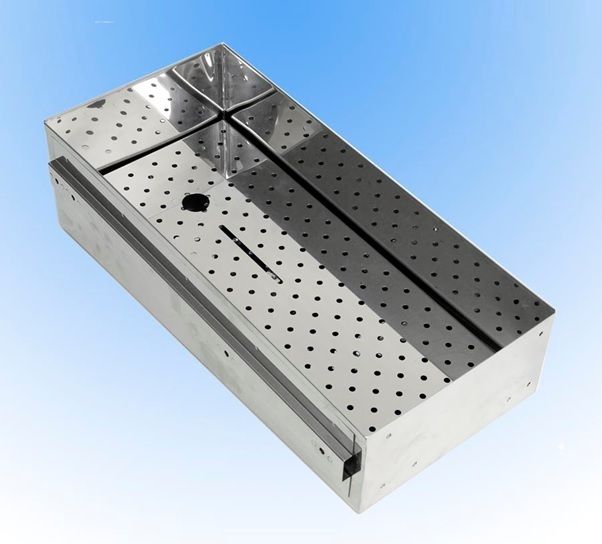

Stainless Steel Fabrication

Price 170 INR/ Kilograms

Stainless Steel Fabrication Specification

- Size

- Custom sizes available

- Heat Resistance

- Yes

- Corrosion Resistant

- Yes

- Product Form

- Sheet, Plate, Tube, Channel, Angle, Custom Profile

- Coating Type

- Optional surface coating or none

- Recyclable

- Yes

- Material Composition %

- Varies by grade, e.g., Cr 18-20%, Ni 8-10%

- Hardness

- 160-210 HB (Brinell)

- Tensile Strength

- 515-620 MPa (for 304 grade)

- Diameter

- As per product specification

- Product Name

- Stainless Steel Fabrication

- Steel Type

- Stainless Steel

- Steel Product Type

- Fabricated Product/Component

- Grade

- 304/316 (others available on request)

- Thickness

- 1 mm - 20 mm

- Shape

- As per design specifications (customized)

- Steel Standard

- ASTM A240 / A276 / Relevant Standards

- Surface

- Polished / Brushed / Matte / Mirror Finish

- Composition

- 18-20% Chromium, 8-10% Nickel (Typical for 304 Grade)

- Application

- Industrial Components, Architectural Structures, Custom Equipment, Interior/Exterior Decor

- Dimension (L*W*H)

- Customized as per requirement

- Weight

- Varies as per design and material thickness

- Color

- Metallic Silver (custom color finishes available)

- Material Grade

- 304, 316, or as specified

- Finish Type

- Polished, Brushed, Mirror, Matte

- Usage

- Fabricated assemblies, supports, frames, cladding, panels

- Forming Method

- CNC Bending, Press Brake, Roll Forming

- Design Support

- CAD/CAM Drawing and Prototyping Available

- Assembly Options

- Mechanical Fastening, Welding, Adhesive Bonding

- Machining Tolerance

- ±0.1 mm or as per requirement

- Cutting Process

- Laser Cutting, Water Jet, Plasma or Shearing as per project need

- Quality Check

- Dimensional, Visual, and Structural Inspection as per ISO standards

- Environmental Compliance

- RoHS and REACH compliant

- Welding Type

- TIG, MIG, Spot Welding and other advanced welding techniques

- Bending Capacity

- Up to 12mm thick stainless steel (varies by equipment)

About Stainless Steel Fabrication

Stainless steel fabricators are professionals who specialize in transforming stainless steel material into functional and aesthetically pleasing products. They use various tools and equipment to fabricate, shape, and weld stainless steel parts and components.Advanced Stainless Steel Cutting and Welding Solutions

Our fabrication process utilizes a variety of cutting methods-including laser, water jet, plasma, and shearing-selected according to project needs. Expert welding techniques such as TIG, MIG, and spot welding enable structurally sound joints and custom assemblies. Each process is engineered for precision and durability.

Precision Forming and Machining Capabilities

We achieve complex shapes and accurate dimensions using CNC bending, press brakes, and roll forming equipment. Machining tolerances are held to 0.1 mm, ensuring fit and performance in high-spec applications. Our forming capacity accommodates stainless steel up to 12 mm thick, supporting a broad range of design requirements.

Comprehensive Quality and Environmental Compliance

Every stainless steel product undergoes rigorous dimensional, visual, and structural inspections in line with ISO standards. Our operations adhere to RoHS and REACH environmental directives, ensuring safe, sustainable fabrication. This commitment guarantees reliability across industrial and architectural sectors.

FAQ's of Stainless Steel Fabrication:

Q: How is the appropriate cutting process selected for stainless steel fabrication?

A: The cutting method-laser, water jet, plasma, or shearing-is chosen based on your project's design, thickness requirements, and precision needs. Each technique offers unique advantages for different geometries and finishes.Q: What are the benefits of using TIG, MIG, and spot welding in fabrication?

A: TIG welding provides clean, precise joints ideal for visible surfaces, while MIG welding suits larger assemblies with strong bonds. Spot welding efficiently joins sheet metals, supporting diverse and complex fabricated products.Q: When should CNC bending or press brake forming be used?

A: CNC bending and press brakes are ideal for shaping stainless steel components with tight tolerances and repeatable angles, typically used when consistent and accurate results are required for industrial or architectural designs.Q: Where are stainless steel fabricated products commonly applied?

A: These products are extensively used in industrial components, architectural structures, custom equipment, and both interior and exterior decor, adapting to specific functional and aesthetic requirements.Q: How are assembly options chosen for stainless steel fabrication?

A: We select assembly techniques-mechanical fastening, welding, or adhesive bonding-based on load, design complexity, and intended application, ensuring optimal structural integrity and installation ease.Q: What quality checks are performed on fabricated stainless steel products?

A: Our comprehensive inspections cover dimensional accuracy, visual finish, and structural integrity, all conducted per ISO standards to deliver reliable, defect-free components.Q: What are the advantages of RoHS and REACH compliant fabrication?

A: Compliance ensures that products meet international health and environmental standards, making them suitable for modern applications and reducing the risk of hazardous substances in finished assemblies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Fabrication Category

Fabricated Steel Steel

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Corrosion Resistant : Optional with galvanized or painted coating

Finish Type : Galvanized, painted, or raw finish

Heat Resistance : Yes

Weight : Varies as per dimensions and thickness.

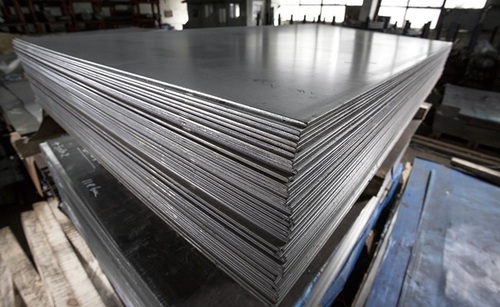

SS Fabrication Raw Material

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Corrosion Resistant : Yes

Finish Type : Polished / Mill Finish

Heat Resistance : Yes

Weight : Depends on Size and Thickness

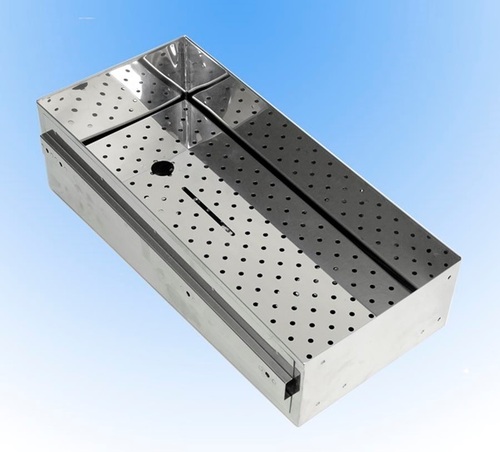

SS Fabrication

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Corrosion Resistant : Yes

Finish Type : Brushed / Mirror / Matte

Heat Resistance : Yes

Weight : Variable (depends on design and dimensions)

Stainless Steel Fabrication Raw Material

Price 170 INR / Kilograms

Minimum Order Quantity : 1 Ton

Corrosion Resistant : Yes

Finish Type : Polished, Matte, Brushed, Mirror

Heat Resistance : Yes

Weight : Varies based on size and thickness

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS