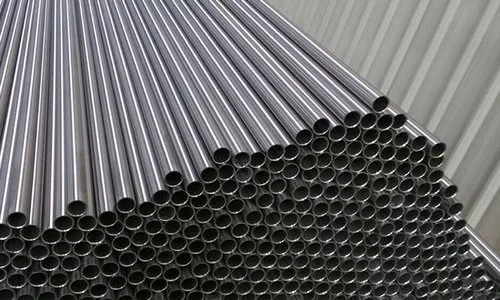

SS IBR Pipes

Price 150 INR/ Kilograms

SS IBR Pipes Specification

- Surface Finish

- Polished, Annealed, Pickled

- Other Material

- Available on request

- Product Type

- SS IBR Pipes

- Alloy

- Yes

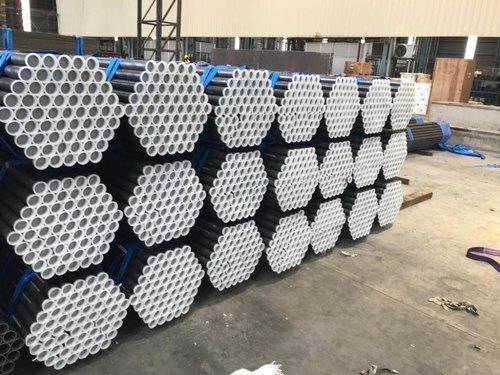

- End Protector

- Plastic Caps

- Connection

- Welded & Seamless

- Application

- Boiler, Super Heater, Heat Exchanger, Power Generation, Petrochemical, Chemical, Oil & Gas Industries

- Material

- Stainless Steel

- Steel Grade

- SS304 / SS304L / SS316 / SS316L / SS321

- Type

- Seamless / Welded

- Shape

- Round

- Standard

- ASTM A312 / ASME SA312 / IBR

- Grade

- IBR Certified

- Surface Treatment

- Passivated

- Technique

- Cold Drawn / Hot Rolled

- Thickness

- 1 mm to 20 mm

- Outer Diameter

- 6 mm to 630 mm

- Length

- 1 m to 12 m (custom as per requirement)

- Tolerance

- 0.5 mm

- Color

- Silver

- Corrosion Resistance

- Excellent

- Min Order Quantity

- 100 meters

- Packing

- Wooden Boxes / Bundled with Plastic Wrapping

- Inspection

- Third Party Inspection Accepted

- Stock Availability

- Ready Stock

- Pipe Marking

- Provided as per IBR requirements

- Pressure Rating

- Suitable for High Pressure Applications

- Test

- Hydrostatic / Eddy Current Test

- Heat Number

- Each pipe with traceable heat number

About SS IBR Pipes

We have been serving our clients with Stainless Steel Seamless Pipe in the market. It is a superior quality tubing option applauded for its seamless construction and exceptional performance. Made using high grade stainless steel, this pipe is devoid of any welded joints, ensuring an uninterrupted and smooth flow. Stainless Steel Seamless Pipe offers high strength, excellent corrosion resistance, and durability, making it suitable for demanding applications in industries such as oil and gas, petrochemical and chemical processing. The design of this pipe eliminates the risk of leaks and enhances structural integrity. With its clean and polished surface finish, the pipe provides efficient fluid or gas transportation.

Engineered for High Pressure and Longevity

Our SS IBR Pipes are specifically designed to perform in high pressure environments found in boilers and heat exchangers. With strict adherence to IBR, ASTM, and ASME standards, and robust testing procedures-such as hydrostatic and eddy current tests-you can trust their durability, safety, and long lifespan even in demanding industrial settings.

Versatile Specifications and Customization

With options ranging from 6 mm to 630 mm outer diameter and 1 mm to 20 mm thickness, our SS IBR Pipes suit a broad spectrum of applications. Custom lengths-from 1 m up to 12 m-are available, meeting specific project requirements. Polished, passivated surfaces and both seamless and welded types ensure optimal performance and easy integration.

Reliable Supply and Comprehensive Support

We maintain a ready stock of SS IBR Pipes for swift delivery and accept third-party inspections for quality assurance. As a trusted manufacturer, exporter, and supplier in India, we cater to minimal order quantities of 100 meters, ensuring flexible procurement for projects of any scale.

FAQ's of SS IBR Pipes:

Q: How are SS IBR Pipes marked and can their origin be traced?

A: Each SS IBR Pipe is marked as per IBR regulations and includes a unique heat number, ensuring full traceability back to its batch and origin. This provides documentation and quality assurance for regulatory compliance.Q: What materials and grades are available for SS IBR Pipes?

A: SS IBR Pipes are offered in various stainless steel grades such as SS304, SS304L, SS316, SS316L, and SS321. Alternative materials may also be supplied on request, accommodating diverse industrial requirements.Q: When are hydrostatic or eddy current tests conducted on these pipes?

A: Hydrostatic or eddy current tests are performed before dispatch to verify structural integrity and detect any defects, ensuring the pipes are suitable for high-pressure applications and meet stringent safety standards.Q: Where can these SS IBR Pipes be used?

A: These pipes are ideal for use in boilers, super heaters, heat exchangers, power generation plants, petrochemical complexes, chemical processing units, and oil & gas industries due to their high pressure and corrosion resistance characteristics.Q: What is the minimum order quantity and how are the pipes packed for delivery?

A: The minimum order quantity is 100 meters. Pipes are securely packed in wooden boxes or bundled with plastic wrapping and protected by plastic end caps to ensure safe transportation and handling.Q: How does the corrosion resistance of these pipes benefit end users?

A: Excellent corrosion resistance ensures long service life, reduced maintenance, and reliability even in aggressive media-making these pipes a cost-effective and durable choice for industrial operations.Q: What surface treatments and finishes are provided on SS IBR Pipes?

A: Pipes can be supplied with polished, annealed, pickled, and passivated surfaces, enhancing appearance and corrosion resistance, and making them ready for use in critical and hygienic environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Pipe Category

Welded Stainless Steel Pipes

Price 150 INR / Meter

Minimum Order Quantity : 100

Material : Stainless Steel

Type : Other, Welded Pipe

Shape : Other, Round, Square, Rectangular

Length : 6 meters (custom lengths available)

Stainless Steel Round Pipes

Price 150 INR / Meter

Minimum Order Quantity : 100

Material : Stainless Steel

Type : Other, Welded / Seamless

Shape : Round

Length : Standard 6 meters, or as required

Stainless Steel Seamless Pipes

Price 150 INR / Kilograms

Minimum Order Quantity : 1 Ton

Material : Stainless Steel

Type : Other, Seamless Pipe

Shape : Other, Round, Square, Rectangular, Oval

Length : Up to 12 meters or as required

SS Seamless Square Pipe

Price 125.00 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Material : Stainless Steel

Type : Seamless

Shape : Square

Length : As per Requirement Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS