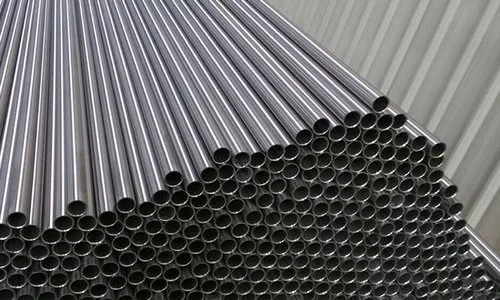

Stainless Steel Round Pipes

Price 150 INR/ Meter

Stainless Steel Round Pipes Specification

- Other Material

- Available in customized alloys if required

- Surface Finish

- Polished, Mirror, Matt, Satin

- Alloy

- Yes

- End Protector

- Plastic end caps

- Application

- Construction, Industrial, Furniture, Architectural, Automotive, Railings

- Connection

- Welded or Seamless

- Product Type

- Stainless Steel Pipe

- Material

- Stainless Steel

- Steel Grade

- 304, 316, 202, 201, or as required

- Type

- Welded / Seamless

- Shape

- Round

- Standard

- ASTM A312 / A213 / A269 / A554, DIN, EN, JIS

- Grade

- 304, 202, 316 (customizable to request)

- Surface Treatment

- Pickled, Annealed or Polished

- Technique

- Cold Rolled / Hot Rolled / Welded / Seamless

- Thickness

- 0.5 mm to 6 mm

- Outer Diameter

- 6 mm to 610 mm

- Length

- Standard 6 meters, or as required

- Tolerance

- 0.1 mm or as per standard

- Color

- Silver / Metallic

- Pipe Form

- Straight Pipes

- Density

- 7.98 g/cm³ (for SS 304) (varies by grade)

- Heat Resistance

- Up to 870°C for grade 304

- Hardness

- Standard / Soft / Hard / Half Hard

- Certificates

- EN10204/3.1, Mill certificates

- Packaging

- Plastic packing/wooden box as required

- Custom Sizes

- Available on request

- Pipe Class

- Schedule 5S, 10S, 40S, or as specified

- Corrosion Resistance

- High

- MOQ

- As per supplier

About Stainless Steel Round Pipes

Stainless steel, which is predominantly composed of iron and chromium, is notable for its remarkable ability to resist corrosion. The incorporation of chromium results in the formation of a protective layer on the surface, so imparting resistance to both tarnishing and rust.Versatile Applications Across Industries

Stainless Steel Round Pipes are extensively used in construction, architectural projects, automotive manufacturing, railings, and furniture making. Their high durability and resistance to corrosion make them a reliable choice for demanding environments. Whether indoors or outdoors, these pipes perform exceptionally in both industrial and decorative settings, meeting international standards for safety and performance.

Customizable Options and Superior Quality

Offered in grades 304, 316, 202, and 201, these pipes are customizable with respect to size, grade, surface finish, and hardness. Various processes such as cold rolling, hot rolling, welding, and seamless methods are utilized based on application needs. Each pipe is supplied with plastic end caps and premium packaging, supported by EN10204/3.1 and mill certificates to ensure traceability and reliability.

FAQ's of Stainless Steel Round Pipes:

Q: What are the common applications of stainless steel round pipes?

A: These pipes are widely used in construction, industrial machinery, furniture, architectural frameworks, automotive components, and railings due to their corrosion and heat resistance, durability, and attractive surface finishes.Q: How can I select the right grade and thickness for my project?

A: Grade selection depends on environmental exposure and mechanical requirements. For high corrosion resistance and heat tolerance, grade 304 or 316 is recommended. The required thickness and schedule (like 5S, 10S, 40S) are determined by the intended load and pressure demands.Q: What manufacturing processes are used for these pipes?

A: Stainless steel round pipes can be produced via cold rolling, hot rolling, welding, or seamless techniques. Each method affects the pipe's mechanical properties and surface finish, allowing customization as per application requirements.Q: Are custom sizes and finishes available?

A: Yes, pipes can be tailored for length (standard or custom), outer diameter (6 mm to 610 mm), thickness (0.5 mm to 6 mm), grade, and surface finish (polished, mirror, matt, satin) based on project needs. Additional alloys and treatments are also available upon request.Q: What certifications and quality standards are provided?

A: All pipes are accompanied by EN10204/3.1 and mill certificates, and adhere to ASTM, DIN, EN, and JIS standards. This ensures consistent quality and traceability for global compliance in critical applications.Q: How are these pipes packaged and delivered?

A: Pipes are typically supplied with plastic end caps, and packaged in plastic wrapping or wooden boxes as required. This ensures safe handling, transportation, and storage to prevent damage or contamination.Q: What benefits do stainless steel round pipes offer compared to other materials?

A: They exhibit superior corrosion and heat resistance, require minimal maintenance, support hygienic applications, possess high structural strength, and maintain their appearance and integrity over time-making them ideal for both functional and decorative purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Pipe Category

Welded Stainless Steel Pipes

Price 150 INR / Meter

Minimum Order Quantity : 100

Type : Other, Welded Pipe

Length : 6 meters (custom lengths available)

Shape : Other, Round, Square, Rectangular

Steel Grade : 304, 316, 202, 310

SS IBR Pipes

Price 150 INR / Kilograms

Minimum Order Quantity : 1 Ton

Type : Other, Seamless / Welded

Length : 1 m to 12 m (custom as per requirement)

Shape : Round

Steel Grade : SS304 / SS304L / SS316 / SS316L / SS321

Stainless Steel Seamless Pipes

Price 150 INR / Kilograms

Minimum Order Quantity : 1 Ton

Type : Other, Seamless Pipe

Length : Up to 12 meters or as required

Shape : Other, Round, Square, Rectangular, Oval

Steel Grade : 304 / 316 / 304L / 316L / 321 / 347 / 904L / duplex & super duplex

SS Seamless Square Pipe

Price 125.00 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Type : Seamless

Length : As per Requirement Millimeter (mm)

Shape : Square

Steel Grade : 202 & 304

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS