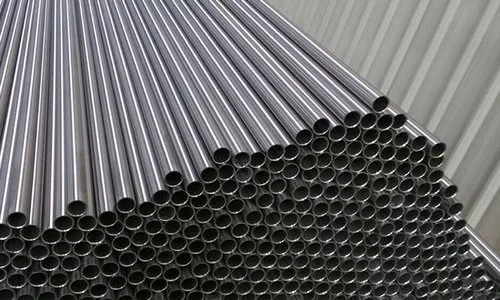

Stainless Steel Seamless Pipes

Price 150 INR/ Kilograms

Stainless Steel Seamless Pipes Specification

- End Protector

- Plastic cap or protector at both ends

- Alloy

- Non-alloy / Alloy (as specified)

- Surface Finish

- Polished, Annealed, Pickled, Bright

- Application

- Petroleum, Oil & Gas, Chemical, Heat Exchanger, Boiler, Food Processing, Construction, Automobile, Pharmaceutical, Power Plant

- Connection

- Seamless/welded ends

- Product Type

- Seamless Stainless Steel Pipe

- Material

- Stainless Steel

- Steel Grade

- 304 / 316 / 304L / 316L / 321 / 347 / 904L / duplex & super duplex

- Type

- Seamless Pipe

- Shape

- Round, Square, Rectangular, Oval

- Standard

- ASTM A312 / A213 / A269 / A312 / A790

- Grade

- AISI, ASTM, DIN, EN, JIS

- Surface Treatment

- Annealed / pickled / passivated

- Technique

- Cold drawn / Hot rolled

- Thickness

- 0.5 mm to 50 mm

- Outer Diameter

- 6 mm to 610 mm

- Length

- Up to 12 meters or as required

- Tolerance

- +/- 0.15 mm

- Color

- Silver

- Hydrostatic Test Pressure

- As per standard or customer requirement

- Pipe Marking

- Specification, Heat Number, Size, Manufacturer Brand (ink marked or stencil)

- Hardness

- 86 max. HRB (for typical grades)

- Corrosion Resistance

- Excellent resistance to wide range of chemicals and environments

- Packing

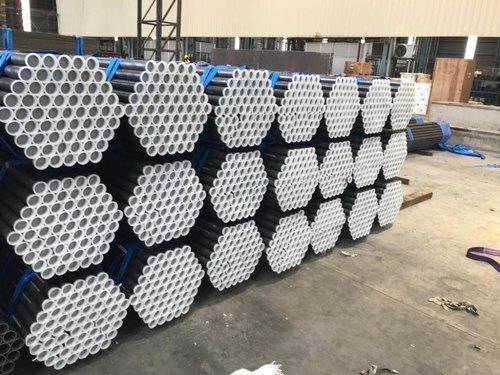

- Bundled or wooden box packing with end caps

- Test Certificate

- MTC as per EN 10204 3.1 / 3.2

- Temperature Range

- -196°C to 800°C (depending on grade)

- Delivery Condition

- Solution Annealed & Passivated

About Stainless Steel Seamless Pipes

Backed by state-of-the-art fabrication facility, we are proposing a wide stock of SS Seamless Pipe. The type of pipe is precisely fabricated from high grade stainless steel with progressive hot rolling technology in complete line with the highest standards of the industry. The pipe has good impact resistance, high durability, super corrosion & chemical resistance and ideal diameter & length, for which, widely demanded in mechanical, engineering and allied sectors. The SS Seamless Pipe comes in many different sizes, grades and finishes.

Other Detail

Features : Durable

Usage: Commercial, Industrial

Engineered for Extreme Temperatures and Conditions

Designed to endure harsh environments and temperature fluctuations, our seamless stainless steel pipes are ideal for demanding applications. Their broad temperature range from -196C to 800C, alongside superior corrosion and chemical resistance, ensures longevity and consistent performance in critical settings such as power plants, petrochemical industries, and boiler systems.

Comprehensive Quality Control and Certification

Each pipe undergoes rigorous testing - including hydrostatic pressure testing as per standard or custom requirements - and comes with a Manufacturer's Test Certificate (MTC) to EN 10204 3.1/3.2 specifications. Our meticulous process guarantees adherence to international standards like ASTM, DIN, EN, and JIS. Pipes are supplied solution annealed, passivated, and fully traceable via ink or stencil marking.

Customizable Options and Secure Packaging

We offer extensive customization, from steel grade and surface finish (pickled, polished, bright) to shape, size, length, and end protection. Pipes are safely bundled or packed in wooden boxes, fitted with end caps to avoid damage during transit. This makes them suitable for delivery across India for dealer, distributor, exporter, manufacturer, and project supply needs.

FAQ's of Stainless Steel Seamless Pipes:

Q: What applications are stainless steel seamless pipes suitable for?

A: Stainless steel seamless pipes are commonly used in industries such as petroleum, oil & gas, chemical processing, power plants, heat exchangers, boilers, food processing, pharmaceuticals, construction, and automobiles due to their superior strength and corrosion resistance.Q: How are the pipes tested for quality assurance?

A: Each pipe goes through hydrostatic pressure testing according to standard or customer requirements and is delivered with a Manufacturer's Test Certificate (MTC) as per EN 10204 3.1 or 3.2, ensuring full compliance and traceability.Q: What temperature range can these seamless pipes withstand?

A: Depending on the selected steel grade, our pipes can handle temperatures from as low as -196C up to 800C, making them suitable for both cryogenic and high-temperature applications.Q: Where can the pipes be delivered and how are they packed?

A: Our pipes can be delivered anywhere across India. For transit safety, they are bundled or securely packed in wooden boxes with end caps or protectors to prevent damage.Q: What is the range of sizes and shapes available for these pipes?

A: We supply pipes in outer diameters from 6 mm to 610 mm, thicknesses between 0.5 mm and 50 mm, and lengths up to 12 meters. Shapes include round, square, rectangular, and oval to suit varied applications.Q: What are the benefits of using seamless over welded pipes?

A: Seamless pipes provide greater strength, uniformity, and resistance to pressure and corrosion compared to welded pipes. They have no weld seam, minimizing the risk of weak points, which is crucial for high-pressure or high-purity systems.Q: How do you ensure the correct pipe is shipped to customers?

A: Every pipe is marked with the specification, heat number, size, and manufacturer brand (via ink or stenciling) for clear identification, supplemented by a detailed test certificate for full product traceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Pipe Category

SS IBR Pipes

Price 150 INR / Kilograms

Minimum Order Quantity : 1 Ton

Product Type : Other, SS IBR Pipes

Type : Other, Seamless / Welded

Length : 1 m to 12 m (custom as per requirement)

Material : Stainless Steel

Welded Stainless Steel Pipes

Price 150 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Welded Stainless Steel Pipe

Type : Other, Welded Pipe

Length : 6 meters (custom lengths available)

Material : Stainless Steel

Stainless Steel Round Pipes

Price 150 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Stainless Steel Pipe

Type : Other, Welded / Seamless

Length : Standard 6 meters, or as required

Material : Stainless Steel

SS Seamless Square Pipe

Price 125.00 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Other, Pipe

Type : Seamless

Length : As per Requirement Millimeter (mm)

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS